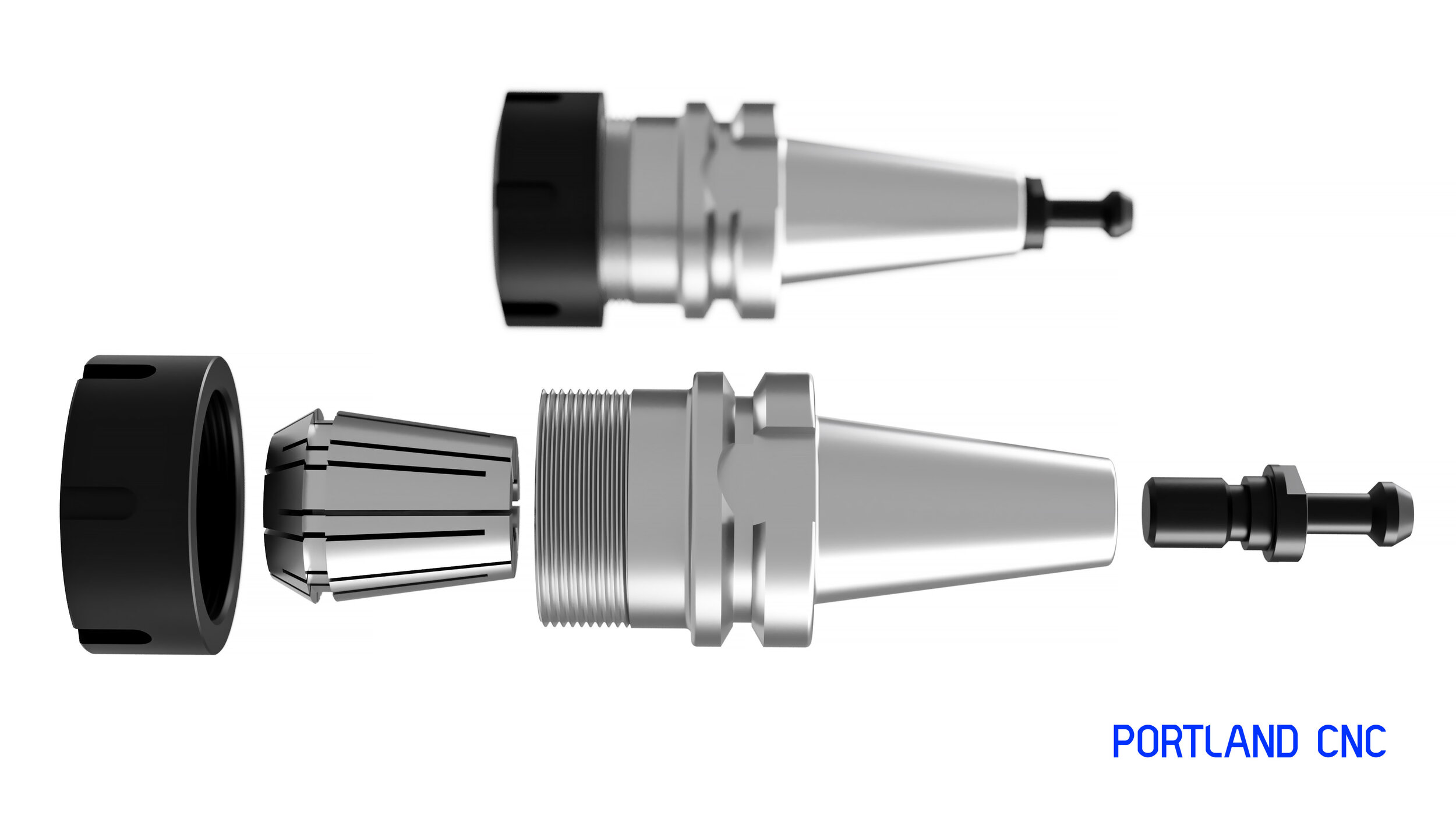

Curious how to properly set up an ER tool holder? Need to know what amount of torque to apply? We’ve got you. Watch the video below and check out the tools

Useful Tools

We highly recommend getting a torque wrench. It’s too easy to over or under-tighten a tool holder and then you’ve got an expensive problem. One stuck tool holder with a nice piece of carbide in it will cost you nearly as much as the torque wrench setup below. You need the wrench and also an adapter.

Torque-wise, we use 80-100 FT•Lbs of torque for ER32 tool holders.

OUR FAVORITE ISO30 TOOLHOLDERS